5-Part AI Playbook Every Ops Leader Needs to Scale Without Chaos

Custom AI Agent to Deploy the Playbook Quickly in Your Organization

Hey Operations Leader,

Earlier this week, I finished reading Steve Jobs’ autobiography, written by Walter Isaacson, for the second time.

I always recommend reading a non-fiction book more than once because you uncover things you may have missed during your first read. It was interesting to revisit the story of Steve’s return to Apple, as it is tied to what I am sharing today.

When Steve Jobs returned to Apple in 1997, he was shocked to find the company buried under a mountain of complexity, dozens of products, tangled manufacturing processes, and bloated systems.

Apple had a sprawling catalog including numerous computer models like the Quadra, Performa, Centris, and several Macintosh variations. Each line was slightly different, confusing consumers and straining internal resources.

The complexity meant Apple was working with multiple manufacturers, suppliers, and logistics providers. This fragmentation not only inflated costs but also caused quality and delivery issues. Manufacturing delays became common, directly hurting customer satisfaction.

Apple’s teams struggled to prioritize. Resources were thinly spread across too many projects. Engineers and designers found themselves juggling competing requirements, leading to mediocre products rather than standout successes.

His first instinct wasn’t to build more technology, but it was to simplify ruthlessly.

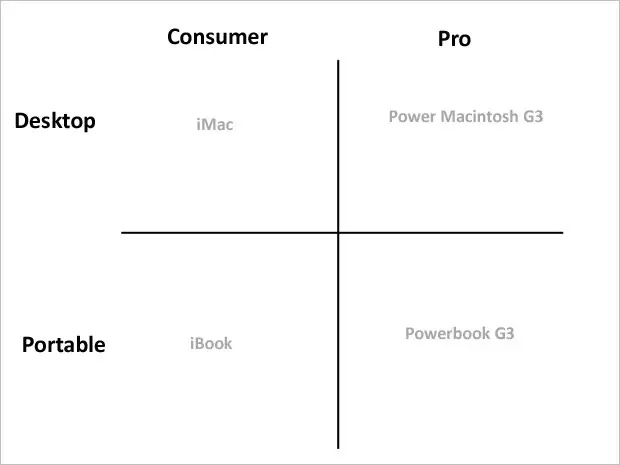

He famously drew a two-by-two matrix on a whiteboard. One axis labeled “Consumer” and “Pro,” and the other “Desktop” and “Portable.” In doing so, he eliminated the vast majority of Apple’s product lines, focusing the entire company on just four products.

Source: Business Insider

This simplification dramatically clarified the company’s mission, streamlined manufacturing, and refocused engineering and marketing efforts. Rather than spreading resources thin, each product now had dedicated teams fully committed to excellence.

Most operations leaders dream of achieving Apple-like simplicity and efficiency. They dive into automation, believing technology alone can untangle their chaos. Yet, they’re missing the Jobs playbook: automation isn’t step one, but it’s the final step.

In my experience leading global enterprise automation projects involving SAP, LLMs, Make/Zapier, Salesforce, Adobe/Google suite, Pricefx, and more, I’ve repeatedly seen teams automating complexity, not simplicity.

But the teams who follow Jobs’ disciplined path first question every process, deleting relentlessly, simplifying thoroughly, and then optimizing manually before automation consistently achieve remarkable scale, speed, and stability.

Like Jobs, these leaders grasp one fundamental truth: Automation isn’t your starting point. It’s your reward.

Today, I’ll share with you the proven 5-step playbook inspired by Steve Jobs’ relentless approach to clarity and discipline. These steps are practical and battle-tested for operations leaders determined to scale without chaos.

I will also give you access to powerful tools that distill my automation experience into a customer assessment template built in Notion and an advanced AI agent built on ChatGPT that will automate the entire playbook for you. (Paid subscribers only)

Given this is a playbook, not a regular post, it will be very detailed, so brace yourself, and let’s dive in.

Table of Contents

5-Part AI Ops Playbook

Step 1: Question Every Requirement

Step 2: Delete What You Can

Step 3: Simplify and Optimize

Step 4: Accelerate the Manual Flow

Step 5: Automate the Proven Flow

Bonus Toolkits for the Playbook (Paid subscribers only ):

Notion and PDF Templates: The Automation Readiness Scorecard and Assessment Template.

Custom AI Agent to efficiently execute your ops automation playbook.

Walk your team through the 5-step playbook, prompting the right questions at each stage. Challenge legacy requirements and identify hidden redundancies in your workflows. Recommend optimizations, suggest process diagrams, and even draft automation-ready SOPs or checklists.

The 5-Part Playbook: How Exceptional Ops Leaders Scale

Steve Jobs embedded simplicity into every operational decision Apple made.

This one decision transformed the company from chaos to clarity, setting the stage for unprecedented growth.

The truth is, most operations leaders approach automation completely backward. They believe technology itself solves complexity, and rush straight into deploying AI tools, APIs, and bots. But in reality, technology without clarity only accelerates confusion.

The world’s best operational leaders follow a proven sequence one I’ve refined from experience across dozens of global enterprise projects.

They achieve automation last, not first. They earn automation by systematically:

Questioning every requirement

Deleting relentlessly

Simplifying and optimizing thoroughly

Accelerating and refining manual processes

Finally, automating only what’s proven and validated

This five-step framework has been battle-tested and proven by many leaders for the last few decades, including Elon Musk, more recently at Tesla, to save millions of dollars in unnecessary complexity and rework.

Let’s break down each step.

Step 1: Question Every Requirement

When Steve Jobs drew that legendary two-by-two matrix at Apple, his goal was that every product had to justify its existence or be eliminated.

Ops leaders, you must apply the exact same principle to your workflows and processes.

Too many businesses inherit outdated procedures without ever challenging their relevance. Fields in forms remain unchecked. Steps in processes go unquestioned for years, sometimes decades. What starts as convenience quickly calcifies into costly complexity.

Let’s take a real-life example.

A Fortune 100 enterprise I consulted for had an SAP integration process for onboarding customers. We discovered their customer creation form had ballooned to 70 different fields. When we dug deeper, only 36 of those fields were actually being used by downstream systems. The remaining 19 fields were just historical artifacts that no one could even remember why they were initially required.

Each unnecessary field meant additional data validation, longer processing times, and increased errors.

Employees spent valuable time managing data no one needed. Worse, these unused fields multiplied the complexity in system integrations and reports, inflating costs significantly.

So we applied Steve Jobs’ ruthless questioning approach, relentlessly challenging each requirement with four critical questions:

Who actually uses this data?

What specific purpose does it serve downstream?

If we delete it tomorrow, what exactly breaks?

When was the last time stakeholders validated its necessity?

By applying these questions systematically, the team confidently eliminated the redundant fields, immediately streamlining customer onboarding and cutting down errors and data rejections dramatically.

Framework in Action

Here’s exactly how you can apply this powerful approach:

List all current requirements:

Start by itemizing every step, rule, field, and process.

Assign ownership:

Clearly identify who originally requested or benefits from each requirement. If no one can own or justify it, flag it for deletion.

Challenge openly:

Ask stakeholders directly:

“How are you using this today?”

“What happens if we remove it?”

“Can you quantify its actual value?”

Conduct a risk vs reward analysis:

If removing a requirement poses minimal real-world risk, eliminate it immediately.

Repeat regularly:

Questioning requirements is never “done.” Schedule periodic reassessments to prevent complexity from creeping back in.

AI Tool to Accelerate Requirement Reviews

Use AI to rapidly highlight unnecessary steps or outdated rules. For example, feed your workflow details into ChatGPT or Claude with a simple prompt:

Here’s our customer onboarding process. Which of these steps seem redundant or outdated, and could potentially be removed without causing problems?This quickly reveals low-hanging fruit, providing immediate clarity and actionable insights.

Step 2: Delete What You Can

When Michelangelo was asked how he created his masterpiece David, he famously replied, “I simply removed everything that wasn’t David.”

Operations leaders can and must apply the same philosophy. Before adding new tools, integrations, or workflows, your priority should always be to remove what’s unnecessary. Deletion is a strategic act of courage, one that separates thriving organizations from those drowning in complexity.

The Real Cost of Complexity

I once consulted for a mid-sized enterprise using SAP and Salesforce to manage thousands of global customer accounts. The complexity of their customer onboarding process was staggering: duplicated customer records for every legal entity, one for “buyback” and another for “non-buyback” customers. Each duplicated record required redundant maintenance, additional data entry, extra approvals, and doubled risk of data inconsistency.

When we traced this duplication back to its origin, we discovered a legacy business rule that had never been questioned or deleted. Nobody felt authorized to remove it, and so it multiplied complexity year after year, costing the company countless hours and tens of thousands of dollars in unnecessary manual work.

Each time I questioned, I got the answer “Sameer, this is how we have been operating this business unit profitably”.

“By creating unnecessary complexity?” I asked.

Crickets!

It definitely takes a lot of courage to challenge years or decades-old business norms.

After overcoming the resistance, we tackled the duplication head-on. Instead of maintaining separate accounts, we simplified the logic by using a single customer record for each legal entity. We introduced a straightforward classification system, simple flags, and partner functions in SAP to indicate the account status.

The impact was immediate:

Reduced data entry efforts by 50%

Eliminated hours of redundant approvals and validations

Significantly improved reporting accuracy and speed

Streamlined system integrations across all systems

Deletion turned out to be the simplest and most impactful decision they’d made in years.

How to Systematically Delete Complexity

Here’s the clear framework you can apply today:

Identify Duplication or Redundancy:

Audit your workflows and data models. Look specifically for repetitive logic, redundant entries, and duplicated processes.

Quantify the Cost of Keeping It:

Clearly measure time wasted, errors generated, and resources consumed.

Envision the Simpler Future State:

Before you delete, define exactly what the simplified future looks like. Demonstrate how less complexity equals clearer processes, fewer errors, and faster workflows.

Build Trust by Piloting Deletion:

Start small. Remove redundancies in one controlled area, then showcase quick wins and tangible results to stakeholders.

Embed Deletion in Your Culture:

Encourage your teams to question and remove complexity regularly. Celebrate deletions publicly as much as new additions or innovations.

AI tools like ChatGPT or Claude can help you pinpoint hidden redundancies rapidly. For example, take your current business process or data model and prompt AI with:

Identify any fields, steps, or rules in this process that seem redundant, duplicative, or unnecessary.Within seconds, you have a hit list for immediate simplification.

One thing to remember, operational excellence is having the courage to delete everything that’s not essential, revealing the streamlined, efficient masterpiece hidden underneath.

Step 3: Simplify and Optimize

After questioning every requirement and removing unnecessary complexity, the next crucial step is to carefully simplify and optimize what remains.

Simplification is a thoughtful, intentional act of refining your processes until they become straightforward and intuitive. Complexity is often mistaken for sophistication, but true sophistication lies in clarity.

Toyota provides one of the best examples of the transformative power of simplifying complex operations. At least until recent years, when they have been struggling to transform into the EV era.

Back in the mid-20th century, Toyota faced intense competition and strained resources, struggling with manufacturing inefficiencies that slowed production and inflated costs.

Their response?

An innovative system, now famously known as the Toyota Production System (TPS).

The heart of Toyota’s approach, instead of focusing only on automation or cutting-edge technology, focuses on ruthless simplification. They reimagined production as a continuous flow of value, systematically removing any element that didn’t directly contribute to building cars faster, cheaper, and better.

For instance, Toyota observed their workers repeatedly walking to fetch parts during assembly, which wasted countless cumulative hours every day.

Rather than automating parts delivery immediately, they simplified by redesigning the workspace itself. Parts bins were placed strategically within arm’s reach of workers, drastically cutting wasted movements.

Similarly, instead of managing extensive inventories of parts which is an expensive and complex proposition they simplified supply chains by implementing “just-in-time” (JIT) inventory management. Parts arrived precisely when needed, dramatically simplifying logistics, storage, and handling.

These simplifications significantly reduced Toyota’s manufacturing cycle time and costs, establishing Toyota as an efficiency leader in the automotive world. Only after these simplifications were fully validated did Toyota layer in automation, ensuring it amplified efficiency rather than complexity.

How You Can Apply Toyota’s Simplification Framework:

Here’s how to systematically simplify and optimize your operations, drawing inspiration from Toyota’s proven playbook:

Visualize the Current Workflow Clearly:

Start by mapping your current process visually, including every decision point and action. Tools like flowcharts, process diagrams, or digital whiteboards (Miro or Lucidchart) work perfectly.

Identify Non-Value Activities (Waste):

Analyze the map critically, asking yourself:

Where are there redundant or overlapping tasks?

What activities do not add direct value to customers?

Which steps regularly cause confusion, errors, or delays?

Apply “Single Decision, Single Rule”:

Simplify complex decision-making logic by breaking down intricate rules into clear, singular decisions. Instead of “If customer A and product X, but also condition Y, then action Z,” simplify to clearly separated conditions:

“If the customer is type A, take action X.”

“If the product is type Y, take action Z.”

Standardize Procedures Clearly:

Define a clear, repeatable process for tasks, ensuring consistency across teams. Toyota famously achieved this by standardizing assembly-line movements to just a few precise, repeatable motions per task.

Optimize Before Automating:

Before deploying automation tools, ensure your manual steps are as efficient as possible. Automation amplifies existing processes, whether good or bad.

Leverage AI to quickly pinpoint redundancies or complexity you might otherwise overlook:

Review this process and suggest specific simplifications or redundancies we can remove.

Rewrite this complex pricing logic into clear, simple if-then statements suitable for automation.Use AI to rewrite overly complicated logic clearly and succinctly.

Prompt example:

Simplified operations translate directly into meaningful business outcomes.

Toyota’s success with simplification became foundational, not only for them but for industries worldwide embracing Lean principles. Like Toyota, the most successful operations leaders understand that simplicity creates scalability, clarity fuels speed, and optimization paves the way for reliable automation.

Faster onboarding and shorter processing cycles.

Reduced errors and higher data accuracy.

Better employee productivity due to less confusion and clearer responsibilities.

More responsive and agile operations are capable of adapting rapidly.

Now, your operations have reached a critical milestone. By questioning relentlessly, deleting ruthlessly, and simplifying strategically, you’ve built a streamlined foundation ready for acceleration.

Step 4: Accelerate the Manual Flow

Many operations leaders mistakenly view automation as the only path to speed.

But if your manual process is slow, cumbersome, or confusing, automation will only amplify your inefficiencies. The next vital step in your playbook, therefore, is accelerating and perfecting the manual workflow. This sets a solid foundation so that automation can later turbocharge a process that’s already finely tuned.

Consider Formula 1 pit crews, which, according to me, is the ultimate case study in manual acceleration.

In the 1950s, pit stops could take minutes. Tires were changed, fuel tanks refilled, and drivers given water and instructions. Over the decades, teams systematically simplified each step, perfected manual execution, and honed precision timing. By 2024, Red Bull Racing achieved a record pit-stop time of just 1.82 seconds. No magic automation, but meticulous optimization and relentless practice.

Before adding technology or robotic equipment, F1 teams spend hours refining their manual choreography. Every step, movement, and task is rehearsed, timed, and streamlined. Automation comes afterward to enhance what has already become world-class execution.

Your operations should follow the same disciplined progression.

How to Accelerate Your Manual Process:

Manual Stress Test:

Run your simplified process manually at least 5-10 times, start to finish. Use real inputs and time every single step precisely.

Identify Bottlenecks:

During these tests, carefully observe where delays occur. Common areas include:

Unnecessary approvals.

Data handoffs causing waiting periods.

Ambiguous roles causing confusion or hesitation.

Minimize Delays Through Parallelization:

Evaluate if certain steps can run concurrently. For example:

Customer approvals and internal reviews might be initiated simultaneously rather than sequentially.

Documents or data gathering tasks could happen alongside system setup tasks.

Develop a Clear Manual Runbook:

Create a straightforward, human-friendly runbook or checklist detailing each task and who owns it.

This reduces ambiguity, improves accountability, and increases speed.

Measure and Refine:

Continually monitor manual performance until it becomes consistent and fast.

Only then are you truly ready to automate.

Feed your simplified process into ChatGPT and ask:

Generate five realistic scenarios to test this process end-to-end manually, capturing likely bottlenecks.

Create a clear, easy-to-follow manual checklist from this simplified workflow, assigning clear roles to each step.You may ask. “But Sameer, why is manual acceleration essential before automation?”

Perfecting a fast manual process ensures automation amplifies speed and efficiency. Think like a Formula 1 pit crew, refine your manual steps until they’re world-class. They first refined human execution to perfection. Only after manual speed was optimized did they consider adding automation to enhance and sustain performance.

This same disciplined approach is precisely how top-tier operational leaders achieve sustainable acceleration. I see several advantages of manual acceleration:

Immediate ROI: Even before investing in automation, you see faster operations and fewer errors.

Simpler Automation: Automation is simpler, cheaper, and more reliable when built upon processes already optimized manually.

Higher Team Buy-In: Teams trust automation built from proven manual workflows, ensuring easier adoption and reduced resistance.

Step 5: Automate the Proven Flow

Automation is seductive, tools are shiny, and AI feels powerful, and the temptation to jump straight into automation can be irresistible.

However, top-performing operations leaders resist this temptation fiercely. They automate last instead of first because automation is only powerful if it amplifies a process that’s already clear, simple, and fast.

Let’s consider the world of airline pilots as a perfect illustration. Despite advances in technology, no airline immediately puts an autopilot system in charge of an airplane from takeoff to landing. First, pilots must manually stabilize the plane, achieve the right altitude, and ensure everything is running smoothly. Only after conditions are stable does automation step in, maintaining consistent speed, altitude, and heading.

Source: Forbes

The logic here is clear and intuitive: if you automate instability or uncertainty, you don’t solve it, then you escalate it. This concept applies equally to your operations.

For example, imagine you’ve perfected your manual customer onboarding process. You’ve questioned every step, eliminated redundancies, simplified procedures, and accelerated manual execution. At this point, automation becomes the natural next step. Now you know precisely what your automation needs to achieve because your manual process has become predictable and repeatable.

When you automate, you’re essentially giving your refined processes superpowers. A manual onboarding process that took an hour now takes minutes. A pricing calculation that required careful manual checks can now run error-free at lightning speed, every time.

Netflix’s Automated Scaling

Netflix didn’t leap directly into complex automated content recommendations or streaming optimization overnight. Initially, they managed content curation and delivery manually, learning user preferences, understanding content trends, and monitoring streaming performance closely.

Over time, Netflix gathered rich insights from this manual approach.

They learned precisely which factors influenced user satisfaction, what signals accurately predicted content preferences, and where operational bottlenecks occurred. Only then, armed with these proven insights, did they introduce powerful automation tools and AI-driven recommendation systems.

The result?

Netflix became synonymous with unmatched personalization, scalability, and customer delight automation amplified an already successful process, rather than attempting to create success from scratch.

When you’re ready to automate your proven manual flows, consider this structured approach:

Start Small and Scale Up:

Initially automate only the most predictable, repeatable components. For instance, automate data transfers, notification triggers, or rule-based tasks. Observe performance closely, and scale automation gradually.

Monitor and Log Rigorously:

Introduce clear monitoring dashboards and logs to track automated performance. Visibility into automated actions builds confidence and enables rapid troubleshooting.

Incorporate Robust Error Handling:

No automation is error-free. Ensure your automated processes include fallback mechanisms and error-handling logic, protecting your operations from silent failures.

Regularly Review and Refine:

Automations aren’t set-it-and-forget-it solutions. Regularly revisit automated workflows to ensure they remain effective as your processes and business evolve.

Prompt AI clearly with something like:

Generate clear conditional logic for automating customer onboarding from CRM to ERP, ensuring minimal errors and clear fallback steps.“”Ultimately, automating proven processes brings transformative business outcomes:

Greater speed and efficiency across operations.

Substantial reduction in human error.

More time freed up for strategic tasks and creative problem-solving.

Enhanced employee and customer satisfaction through predictable, high-quality experiences.

Automation isn’t there to fix problems mid-flight; it exists to maintain steady, predictable excellence once manual control has achieved stability. The same is true for your operations. Automation doesn’t rescue flawed processes but it magnifies perfected ones.

Bonus: Automation Readiness Scorecard & Your Custom AI Agent

Before you rush into automating, slow down and ask: Are you truly ready, or just eager to move faster?

The world’s best ops leaders use brutally honest self-assessment before flipping the switch.

I’ve spent years in the trenches, refining every part of my automation playbook, testing what actually works in the real world, and discarding the hype.

Now, for the first time, you can access the exact advanced AI tools (ChatGPT Agent and custom Notion templates) that have helped leaders unlock hours of their time and finally scale without chaos.

If you have a paid subscription to Solve with AI, then you can download using the link below or join as a paid subscriber and get instant access to everything I wish I’d had when I started.

The Automation Readiness Scorecard and Custom ChatGPT AI Agents

Download links:

Keep reading with a 7-day free trial

Subscribe to Solve with AI to keep reading this post and get 7 days of free access to the full post archives.